BOM Costing

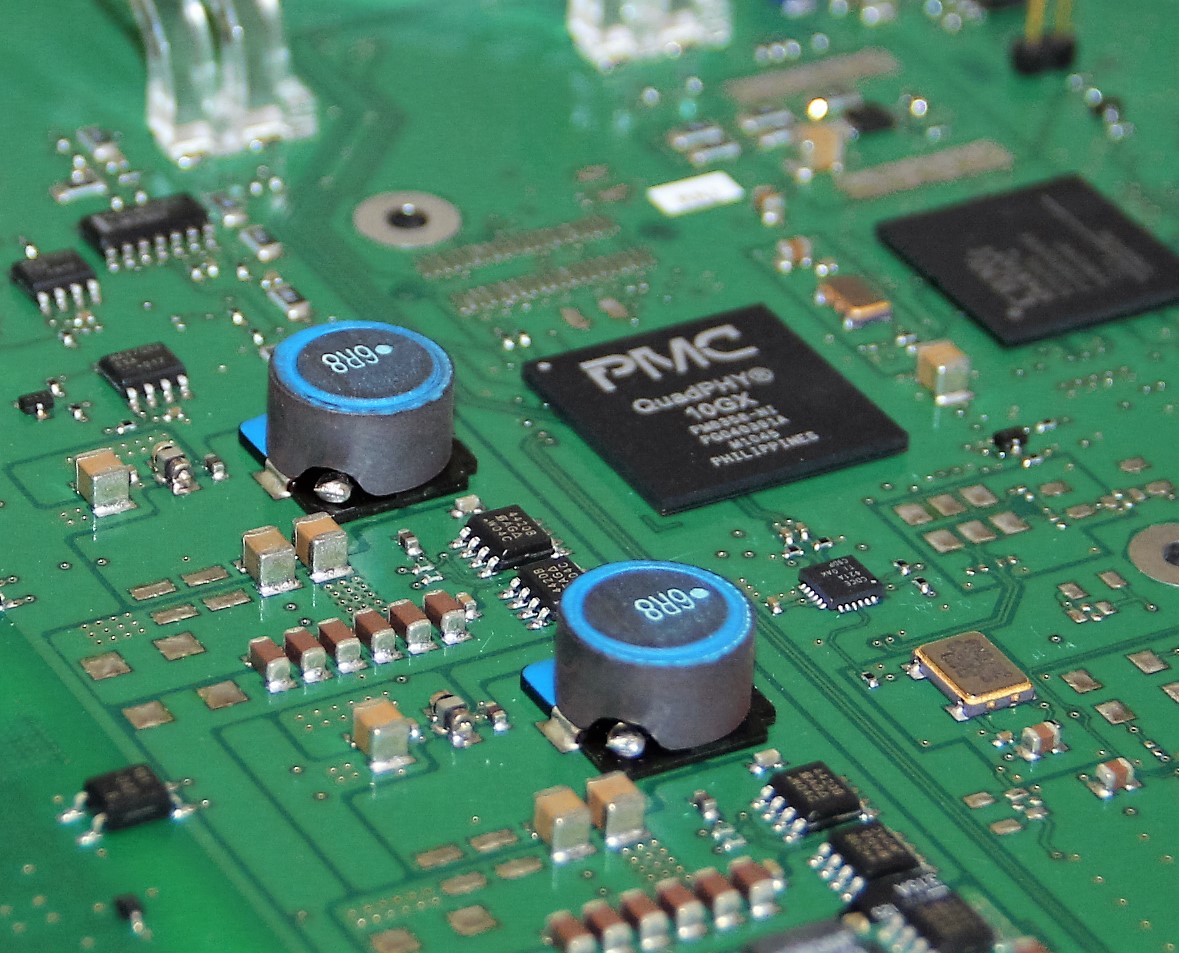

BOM costing in the electronic manufacturing business can be a challenging exercise.

For your customer - the OEM Company - to successfully outsource the production of a printed board assembly, a clear and complete bill of material (BOM) is a prerequisite.

In reality and certainly in the early NPI stages of a new project the BOM is often not too well documented and this can make life difficult for you in preparing a winning quotation.

A clean BOM should include for each line the approved manufacturer, the full manufacturer part number and the package type, at least.

Missing or wrong information on the BOM, sometimes only a few characters or digits in a part number, can cost a great deal of money.

We are experienced to support you in all aspects of BOM management:

- Validation of manufacturers, part numbers and footprint

- Costing

- Availability and Lead-time - VLT

- Rohs compliancy analysis

- Packaging type

- Minimum package quantity - MPQ

- Minimum order quantity – MOQ

- Life-cycle status

- Second source analysis

Contact: info@woutersenwouters.be